EPR: Preparing for a Packaging Material Shift

What to Know

Companies must comply with a patchwork of EPR packaging laws and their recycling goals.

EPR programs require fees based on volume and sustainability of packaging materials.

Shifting to recyclable, compostable, and reusable packaging materials results in the lowest EPR fees.

EPR Has Gone Global

Extended Producer Responsibility (EPR) has become a fundamental element of global sustainability frameworks. Most recently, the EU has introduced the Packaging and Packaging Waste Regulation (PPWR) which began in August 2026 and is designed to harmonize and strengthen EPR in all member states.

In the US, multiple states have already implemented packaging EPR laws, with more on the books for the future and others exploring EPR regulations through needs assessments. That means staying competitive and minimizing fees will require significant shifts in packaging supply chains to prioritize sustainability.

The Need for a Material Shift

With the tide of EPR rising, the smartest thing companies can do after reducing packaging by volume is to change their packaging materials. Proactively switching to sustainable materials better positions companies for future compliance needs while reducing fees tied to the patchwork of existing EPR laws. When planning for a material shift, leadership needs to consider:

Which materials generally yield lower EPR fees

Material options available

Key challenges of each potential material

Consumer preferences

This article will help shape your roadmap to an EPR-friendly packaging supply chain.

Understanding Eco-Modulated Fees

The majority of packaging EPR programs in place use eco-modulated fees to incentivize the use of more sustainable materials.

Eco-modulated fees are a fee system that adjusts the costs producers pay for EPR programs based on the recyclability and overall environmental impact of their products and packaging.

Products and packaging that have positive environmental attributes incur fees lower than the baseline, while products and packaging that use materials with a negative environmental impact incur fees significantly higher than the baseline.

Materials with a positive eco-modulation impact are:

Easily recyclable

Refillable

Use recycled content

Have a minimal design

Materials with a negative eco-modulation impact are:

Difficult to recycle

Single-use

Hazardous

Have a complex or high-volume design

EPR Packaging Evaluation Criteria

The optimal range of packaging for producers under EPR is highly individual. When evaluating packaging materials, these criteria should guide your selections:

Recyclability, compostability & circularity

Availability & supplier maturity

Initial & total landed cost

Barrier & functional performance

Compatibility with existing infrastructure

Safety & food contact compliance

EPR-Friendly Materials

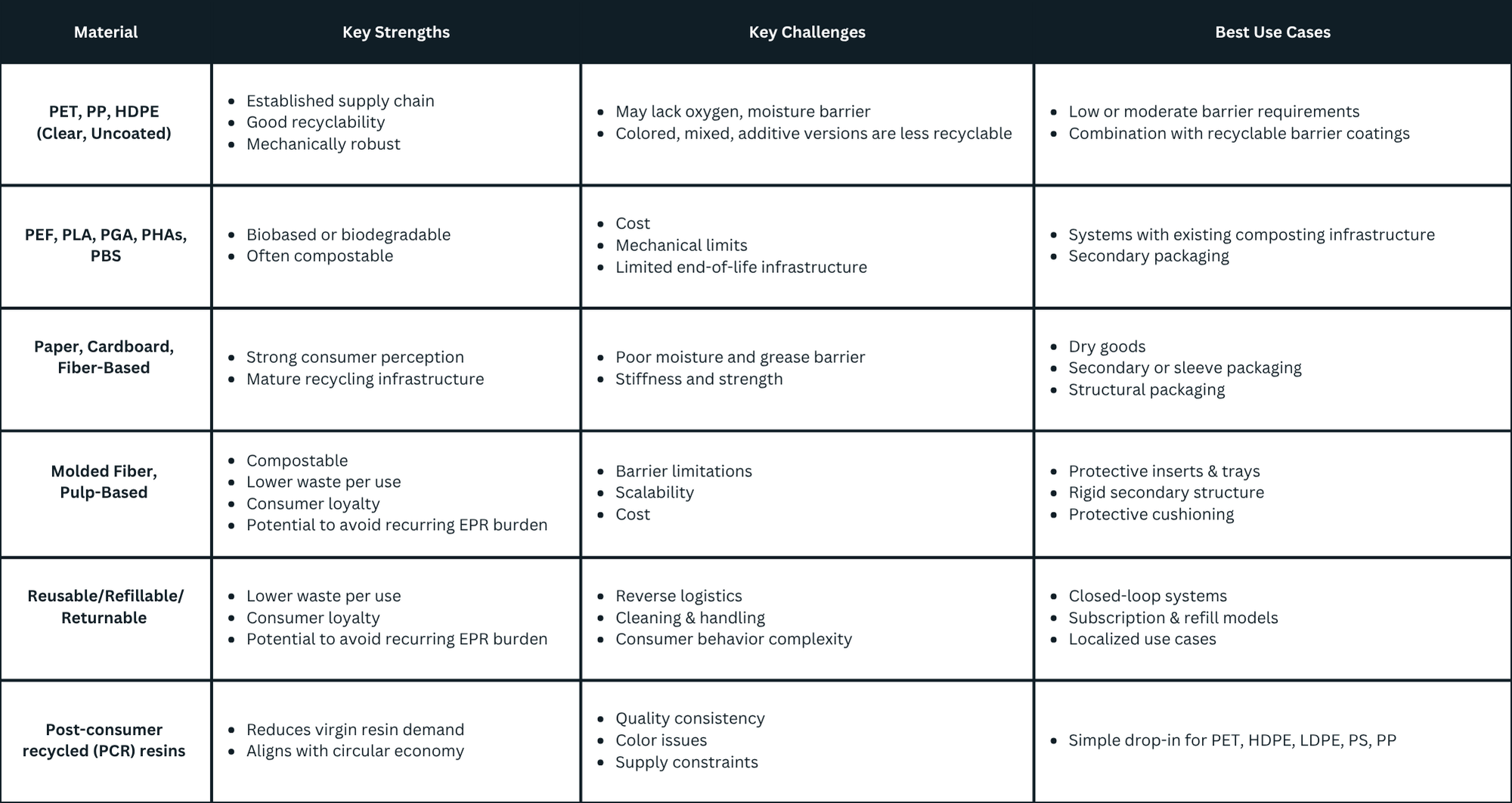

There’s a vast range of materials available to EPR producers, but these six are the most readily available and commonly considered.

Considering the Consumer

When investigating the best path to a material shift, it’s important to consider consumer sentiment. McKinsey research indicates that about 39% of global consumers rate environmental impact of packaging as “very important” important in general. Research from DS Smith shows that in a shipping package, sustainability is the #1 most important attribute and consumers expect clear communication on sustainability credentials.

Customers show clear material preferences, associating glass, paper, and metal most closely with recyclability and sustainability. At the same time, there is still a significant gap in which consumers say they’re willing to pay more for sustainability packaging but their real-life behavior contradicts their claims and cost remains a top factor in practice.

The top 3 keys to consumer consideration in EPR-friendly material shifts are:

Price point gap

Familiarity with material

Pre-existing perceptions

Material Shift Best Practices

Shifting your company’s packaging materials requires a long-term strategic approach and the flexibility to adapt to changing regulations. Follow these three core best practices when shaping your EPR strategy.

Target materials with existing integrations into local recycling systems.

Prioritize single-material packaging over complex composites.

Track fee schedules and incentives in each state where you do business.

Snaplinc: Your Full-Service EPR Consultant

EPR compliance is a long-term commitment that can overwhelm even seasoned compliance professionals. Working with Snaplinc gives you one-on-one access to EPR experts that can guide you to compliance today and develop strategy for tomorrow. Adjusting your packaging for EPR requirements results in lower fees and compliance in multiple states as laws develop, but it’s a multilayered process that needs careful consideration. Schedule a meeting with Snaplinc Consulting to learn how we can help shape and guide your EPR compliance program for maximum long-term success.